DT12 TRANSMISSION – WESTERN STAR

MAXIMUM FUEL EFFICIENCY. FRONT TO BACK.

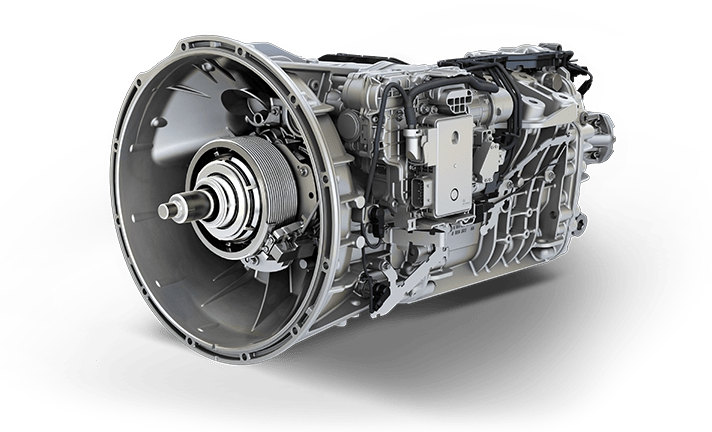

- Integrated communications benefits: The DT12 transmission links engine to axles, and communicates with every model in the Detroit engine lineup on an integrated electronics network to share damage-reducing information such as clutch overloading and driveline protection.

- Super-finished gears: Tightly-spaced 12-speed gearing, now with “super-finished” gears in the new DT12, improves low-speed manoeuvrability, making the Detroit powertrain not only strong and efficient, but also smooth and safe to operate as well.

Intelligent powertrain management (IPM)*: The DT12 uses GPS technology and information from a topographical map to manipulate both engine and transmission functions, taking advantage of the truck’s surroundings. IPM refines the parameters of this technology, making the truck even more capable of utilising its surroundings for maximum fuel efficiency.

Transmission benefits: The DT12’s gearing, along with eCoast, are integrated with Detroit’s DD13 and DD16 engines for optimised fuel economy.

* Vehicle specification may vary by market and some features may be optional equipment.

MAIN HEADING

MULTI LINE HERE

A proud tradition of building engines with strength, quality and dependability began for Detroit® in 1938, when it was known as the General Motors (GM) Diesel Division. The heavy-duty, on-highway Series 71 engine was used extensively in military and road-building and was followed by the Series 53 model, another powerhouse with wide-ranging applications.

2,250 – 2,500 lb-ft

MAX INPUT TORQUE

OVERALL RATIO

72,500 – 150,000 kg

*Higher GCM available on request, dependant on specification and application

GCM Limit

Text

- Large, robust gears for tough jobs. The DT12-OV and DT12-OVX feature large, robust gears that allow for increased gross combination mass (GCM) and input torque. Thousands of hours of rigorous testing have made the DT12-OV and DT12-OVX transmissions purpose-built to take on rugged environments.

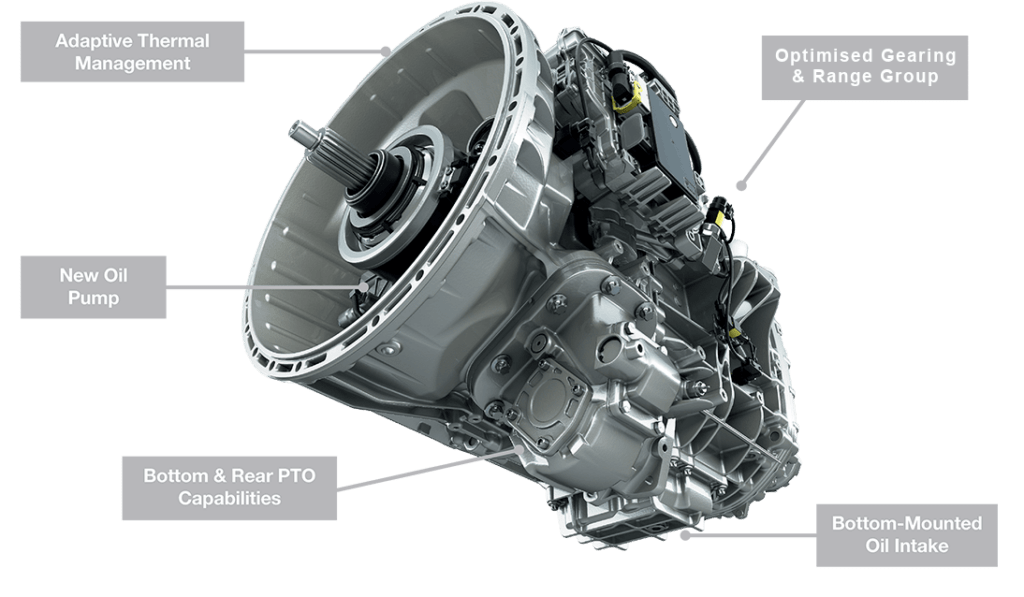

- An improved oil system design. A new oil pump provides a more continuous flow of oil at all speeds and operating conditions. Its bottom-mounted oil intake also allows oil to be picked up at the lowest level and sprayed onto the gear mesh, ensuring ample lubrication in tough conditions—and less parasitic loss due to oil splash.

- Enhanced thermal management for greater reliability. The oil cooler’s adaptive bypass valve maintains oil at an optimal temperature for any running application. This cools oil when it’s needed and bypasses when it’s not.

- Bottom PTO capability for increased application coverage. In addition to rear power take-off (PTO), the bottom PTO capability of the DT12 transmissions provides flexibility and dependable performance for any industry, from heavy haul to logging, construction, farming, and mining. Dual PTO usage (bottom and rear) opens up even more ways to work.

Add Your Heading Text Here

Performance on demand.

- Off-Road Mode features shift maps that give you peak performance on any terrain.

- Rock-Free Mode helps you avoid wheel-stuck situations by using the accelerator to rock the vehicle free.

- Paver Mode allows a dump truck to shift from neutral to drive without pressing the brake pedal while moving away, ensuring a steady flow to the paving machine.

- The Power Launch feature automatically increases engine speed to 1,200 RPM to ensure smooth, powerful take-offs with heavy loads—all while protecting the clutch and driveline.

MAIN HEADING

MULTI LINE HERE

A late-1980s joint venture between Penske Corporation and GM created Detroit Diesel Corporation. In 2000, Daimler-Chrysler acquired the business, making Detroit Diesel a subsidiary of Daimler Trucks North America. In 2011, Detroit Diesel expanded its design and manufacturing scope beyond engines, simplifying its name to Detroit®. Today, Detroit® products and services are supported by a parts and distribution network of over 800 locations in North America.